GOLD TECHNO Group found in 1996 and GOLD TECHNO CASTING FOUND IN 2018.Sister concern unit of Gold Techno Art Foundry at Kheda Ahmedabad. This facilities with ultra-modern machines and equipment’s. That quality is meet domestic and international platform. The company is conscious about its responsibility towards environment. The manufacturing processes a machinery are environment friendly. The products are manufactured based on client requirements, right from raw material purchase the finished products, client preferences and needs are factored on top priority and up to the customer requirements.

Objective of the company is to concentrate on qualitative approach for casting manufacturing, have in continuous developments according to the current trends in steel and alloy casting products Butterfly Valve Manufacturers in Gujarat. We have qualified and expert manpower with core technical knowledge. Accuracy, and on-time delivery are our primary concerns with respect to customer satisfaction.

Manufacture Steel Casting, Stainless Steel / Alloy steel Cast Products and Manganese Steel We can provide semi machined as well as fully machined _nished casting products as per customer requirements. We can provide castings for pumps & valves industries, mining & mineral, oil processing industries, paper industries, chemical industries and various engineering.

Our install plant capacity 5500 ton with our corporate once and plant spread over 60000 sqft near Kheda, Ahmedabad, Gujarat, India. The premises provide work friendly, healthy and ideal environment. Due versatile design of sophisticate equipment, we have advantage to develop wide range of products consisting high and low alloy steels. ensures the quality expectations of us customers’ requirements as per the national and International standards

GOLD TEHCNO CASTING mission is to:

With our knowledge and technology, delivering quality casting products to our valuable customers with respect to their expectations and building a strong structure of long-term business relations

Manufacturing of Highest Quality Castings in All Metallurgical Grades Such as Stainless steel, Duplex and Super Duplex Steel, Inconel Grades, Alloy Steel, Carbon Steel, Nickel Based Alloys confirming to various IS, ASTM, BS, DIN & Other Indian &International Specifications.

We Have Been Manufacturing Highest Quality Castings in All Metallurgical Grades Such as Stainless steel, Duplex and Super Duplex Steel, Inconel Grades, Alloy Steel, Carbon Steel, Nickel Based Alloys and Have Earned a Reputation in Various Core Industries Such as Pumps, Valves, Cement, Chemical, Marine, Mining, Power and General Engineering.

Our factory Has a Well-Developed Infrastructure with An In-House Laboratory Equipped with All Modern Testing Instruments Such as Optical Emission Spectrometer, Ultrasonic Testing Machine, Impact Machine, Hardness Testing Machine and Magnetic Particle Testing Device etc. GOLD TECHNO CASTING Has Maintained Focus on 'Customer First' Philosophy by Investing in Delivering Quality Products, On-Time Deliveries & Value to Customers All Over the World.

Induction furnace 2500 KW medium frequency Induction Furnace, Make: Inductrotherm (India) Pvt. Limited Ahmedabad 3000 Kg. & 7000 Kg. Crucible

Automatic resin sand mixer and Omega with PLC control (For Two part _notch moulding process) Pneumatic Ramming Machine, Mould Hardness Tester

Customer Wise Pattern Stacking Arrangements. In-House Pattern Modification & Repairing Facility.

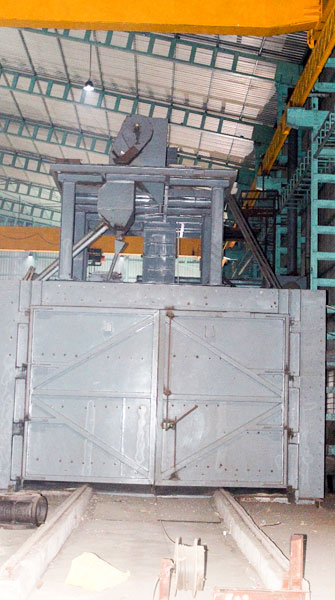

Solution Annealing - Furnace number 1, Solution Annealing - Furnace number 2, Annealing & Normalizing - Furnace number 3

Swing Frame Grinders, Flexible Shaft Grinder, Shot Blasting Machine (Table size 4M), 1000 AMP. Rectifier't,'Welding Machine, Air SC`e.'N compressor 185 dm IR Make, Pneumatic Chipping Machine, Pneumatic pencil grinder

For third party testing, we have tied up with the following parties in Ahmedabad/Vadodara which are approved by NABL, EIL, JBR, Lloyds & all major Third-Party Inspection agencies.

EOT Crane 5 MT, 10 MT, 15 MT, 20 MT, 25 MT Capacity.

Vertical Boring Machine 100mm Spindle Dia, Vertical Boring Machine 75mm Spindle Dia, Vertical Boring Machine 12100rnm Spindle Dia, Milling Machine, Planner Machine, Shaping Machine, Radial Drilling

Gold Techno Casting has modern Quality Control facilities. This enables the company to manufacture various critical grades of alloy steel castings conforming to national and international standards.

Spectrometer Model – Bruker Q4 TASMAN- With Fe, Ni & Cu base for testing of C, Si, Mn, Cr, Ni, Mo, Ti, V, W, S, P, Nitrogen Channel (41 Channels) & Other Related Elements Are Checked Up to Three Decimal Accuracy.

a) Universal Testing Machine - Range 600kN b) Impact Testing Machine: 300J Charpy c) Digital Rockwell cum Brinell Hardness testing Machine d) Metal Temperature PYROMETERS 1000°C - 1700° C Contact Type

a) Radiography – Outsourced (In some time In House Facility Available) b) Magnetic Particle Testing - In House c) Dye Penetrating Test - In House d) Ultrasonic Testing – In House